If I say “process” which definition comes to mind?

– A document that needs to be in certain format and tells you what to do.

– Technical word that has many interpretations depending who uses it.

– Technical word for activity with a purpose.

– I don’t even know what it is.

Whatever your answer was, the reality is that the word “Process” means something different to each individual. It is no wonder that the Phrase “Process- based Approach” is not well understood. To be honest, when we go to different companies as consultants, we have noticed that “Process approach” has taken many shapes and forms in different organizations. So let’s try to breaking it down and simplifying it by defining it correctly and showing you the importance of it.

Defining Process Approach- Elementary level

So, what is a Process?

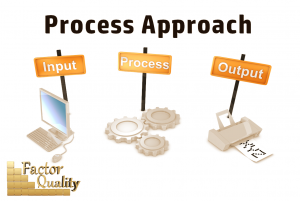

A Process is a something we do to get something done/ completed. Too simple, you say? Okay, let’s reword it. A process is an activity that converts an input into an output.

What is Process-based Approach?

Process approach is simply a way of looking at all your activities and thinking of them as sets of inputs and outputs. I like to tell people to think of it as a chain of activities, where one process feeds into the next.

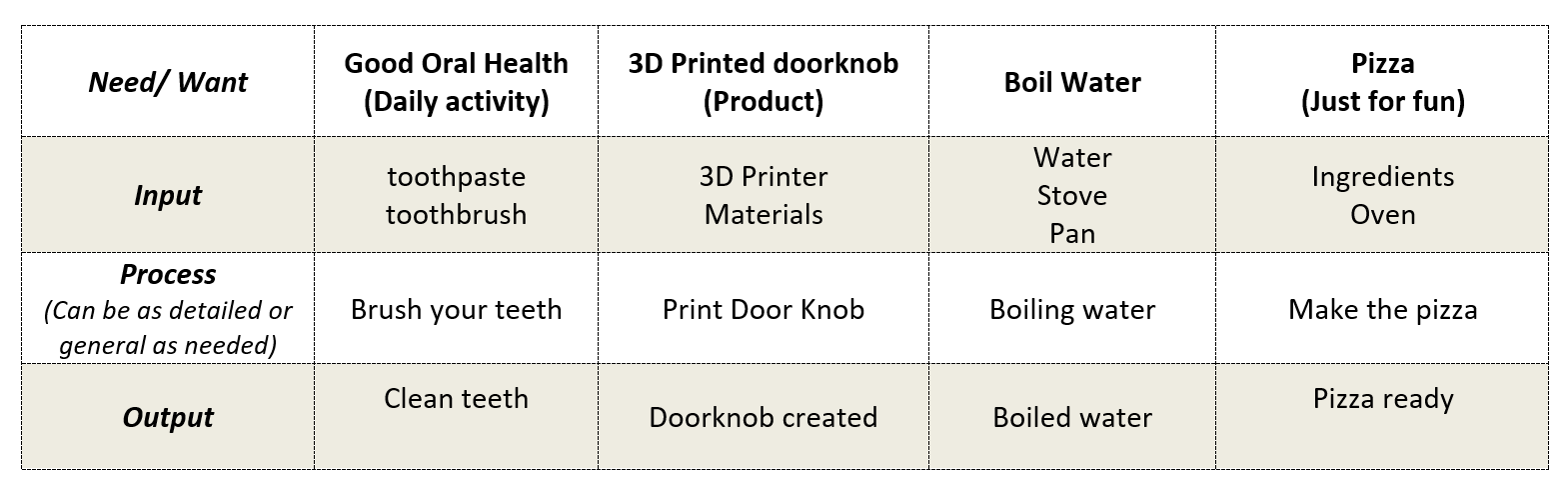

So, let’s start visualizing this: INPUT – PROCESS – OUTPUT

Getting something done – Process

1. We have a need/ want to get it done- this is the TRIGGER.

2. You will need some items to start the activities – this is called INPUT.

3. You will work on it, this is called PROCESS (activity[ies])

4. Once finished with the process you will have a final result, this is called OUTPUT.

So let’s use this elementary definition and apply it to the real world… you’ll notice that process approach can be found everywhere.

Defining Process-based Approach – College level

You might be thinking, “Wait, that is too simple. That cannot be what ISO 9001 is really looking for.”

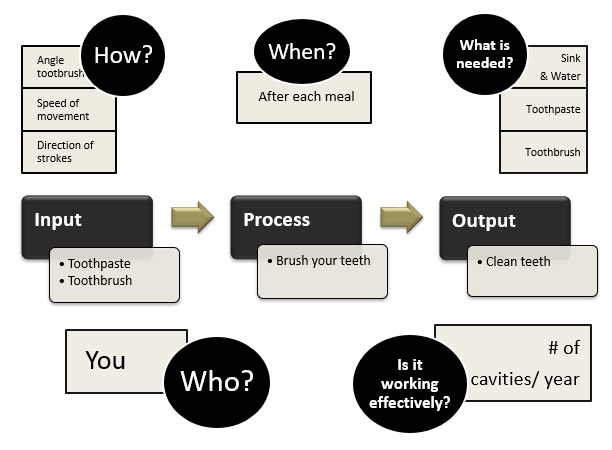

You are right! We do need to take it a step further. Other than just looking at: INPUT-PROCESS-OUTPUT, ISO wants us to understand basic elements within the process to make sure it works correctly.

ISO 9001 basically expects us to break down each process to understand the following:

– How is it done?

– When is it done?

– Who does it?

– What is needed, to get done?

– How do you know it is working effectively?

So let’s take a look at one of our previous processes and take a deep dive. Let’s look at brushing your teeth.

(I will deep dive into 1 of them, you can do the other 3 for practice. You are more than welcome to send us an email with your results and we can check them and give you free feedback. It is good practice. Email: info@factorquality.com )

Okay in business we have a lot of processes (activities with purpose). For instance, to name some: selling, purchasing, designing, manufacturing and so forth. But beware, not every business activity needs to be broken down! The key processes (those activities that your business would not survive without) are the ones you need to focus on. Just by putting it down on “paper” and breaking the process down as above you will find a lot of clarity for your business and you’ll be able to notice areas of improvement for each process and if there are any potential breakdowns between processes.

Why should we use process approach?

Although we are used to looking at businesses and sectioning them up into departments, by using the process-based approach we make sure each process delivers outputs to the next process always working towards achieving the same common goal. By managing your QMS using process-based approach, you understand that processes need to have a common goal that threads them together; for example customer satisfaction. Further you need to understand that all these processes depend on each other in order to deliver what the customer needs. Once you are able to break processes down, like we did with the “tooth brushing” process example above, then you can understand what areas, if any, can be improved within each process.

Factor Quality experts always start all projects by learning how your processes work. Just by interviewing you we can tell which processes are not seen as important as others, if there is a united vision/direction and finally, we learn how you monitor effectiveness throughout your activities. While each department has their own (different) processes within, they might not fit into the quality management system because they are not key to your success as a business, our experience helps us immediately know which processes are key to your QMS and which should be focused on.

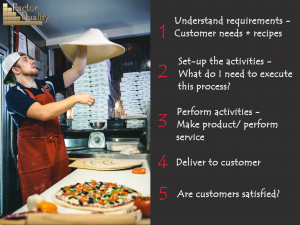

You remember that QMS blog where we put the pizza parlor as an example? Let’s bring it back…

In there for example there are several key processes we need to notice:

1. Sales + Marketing

* Creating interest for product

*Order creation

2. R&D

*Recipe creation

3. Purchasing

*Supplier & Inventory management

4. Cooking

*Equipment management (calibration & maintenance)

*Delivery

5. Customer feedback (Quality Management)

Once you start using “Process-Based Approach” then you’ll notice benefits that will be important for your business such as:

1) Key processes working together in sync will ultimately result in positive customer satisfaction.

2) If the outputs of one process are not done well, it will impact the next processes.

3) Within the details of each process lie the improvements. Improvements will always be welcomed by your customers.

4) Finally, your business is expected to be measuring the performance of each process to make sure they are effective and to ensure quality of

your service or product is being achieved.

FQ TIP: Remember that when you are trying to apply this valuable quality principle into your business, make sure you keep it simple so that changes, improvements, fixes are not too overwhelming to your business.