ISO 9001 Haters will hate

On one of our ISO 9001 promotions on Facebook last year a person commented: “Joke”.

Isn’t this what people call a “hater” right?

We checked our links, forms and webpage to ensure they were working correctly. Then we took a few deep breaths several times before answering as amicably as possibly.They never responded back to let us know what they meant.

Why be nice to a hater?

Over the years in quality management, I have learned that for every fierce ISO 9001 supporter there is the same amount of ISO 9001 haters.

Do we blame them? No! Actually, we can empathize.

I cannot tell you how many small machine shops have lost their largest customer because they did not hold an ISO certificate!!!! And to add insult to injury, their customers went to competitors that were not as good but had that cert.

I have also met small business owners that could not get certified because it is way too EXPENSIVE and the return on investment (ROI) is not always guaranteed. For a company of 10-20 people, spending 10k on average for a consultant that will help them get ready and then another $8k – $12k for the 3 year certificate. This is a huge investment for many, and a decision cannot be made lightly.

If we could make the whole process more affordable, it would help people be more open to ISO. Don’t you think? (Hint-Hint/ Wink- Wink: check out our modern consulting program it is one of few affordable programs out there). However, there is much more than lowering costs in order to make ISO less hated.

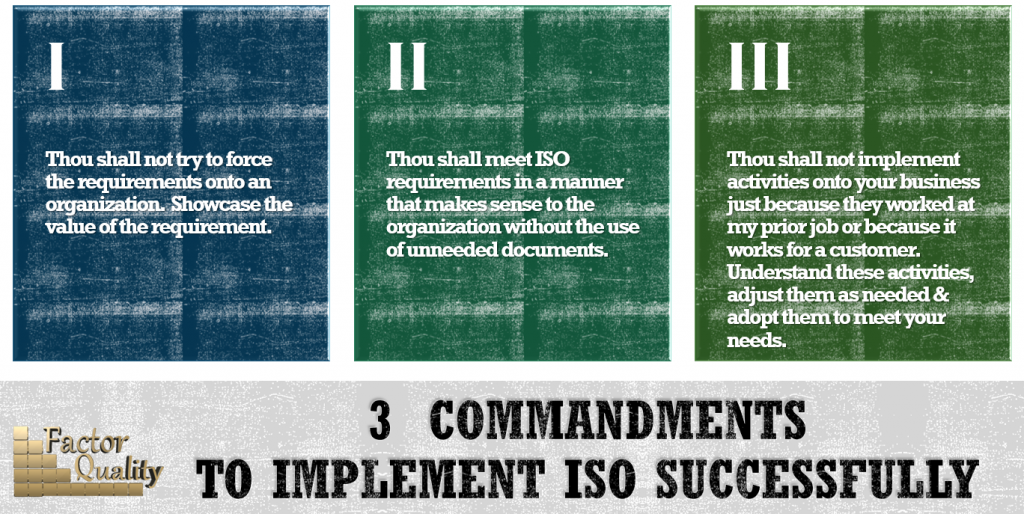

I believe the key to making ISO a less hated subject is by following 3 simple rules:

1) Stop forcing ISO, embrace ISO.

First, we need to stop forcing companies to get certified. Instead we need to help them change their mindset. Change management skills are key here. They need to understand the value of ISO 9001 and implement ISO without adding more work for the businesses. Forcing ISO 9001 requirements on companies drives resistance within a company. It makes the implementation of the ISO system only that much harder. On top of that, people do not take care of anything that they feel are forced into. These activities need to make sense for them to care to maintain them.

change their mindset. Change management skills are key here. They need to understand the value of ISO 9001 and implement ISO without adding more work for the businesses. Forcing ISO 9001 requirements on companies drives resistance within a company. It makes the implementation of the ISO system only that much harder. On top of that, people do not take care of anything that they feel are forced into. These activities need to make sense for them to care to maintain them.

Check out our blog about keeping it simple, where it explains thoroughly why forcing ISO does not work.

2) Make sure ISO makes sense to your business.

A few months ago, a Quality Manager reached out to me, asked me if I could come visit them and talk about transitioning their QMS. He was not sure if the company needed to transition their QMS to the ISO 9001:2015 version. I went to meet the QM and the President of the company to discuss transition needs. As soon as we said our hellos, they were very candid and told me that they were struggling with the idea of having to invest time and money in updating their QMS. They mentioned that their QMS was a burden and instead of helping them it was in the way of progress and innovation. They wanted to be dynamic and responsive to their customer but could not. They went on and on with examples of things that were not working and the more they explained, I realized that their problem was not the ISO 9001 requirements, but it seemed that the problem is how they set up their QMS in their business.

To add to this, they also told me that sales & marketing had made the push to get certified to attract more customers, but they never got more customers. As far as they were concerned, none of their current customers cared if they were or not certified. In my head, I asked myself why continue with their ISO certification, when they are having so much issues with it? As a business owner myself, I do not waste my time on things that do not benefit my customer. So, I told them something that hindered my own consulting business, but I thought was the right thing to do as a business owner myself.

To add to this, they also told me that sales & marketing had made the push to get certified to attract more customers, but they never got more customers. As far as they were concerned, none of their current customers cared if they were or not certified. In my head, I asked myself why continue with their ISO certification, when they are having so much issues with it? As a business owner myself, I do not waste my time on things that do not benefit my customer. So, I told them something that hindered my own consulting business, but I thought was the right thing to do as a business owner myself.

“ISO 9001 is a beneficial management system, but only when done in such a way that you see value to it and not feel like it is a burden. If your customers don’t care for it, there are no new avenues you could get out of it, then, why get certified again right? But if you do decide to keep your certification, then I suggest you get a consultant to review your processes and help you de-clutter your QMS to make it valuable to you.”

As expected, at the end of the week, they decided to drop their QMS. This was not surprise at all, there are many that just give up on their QMS. This is not uncommon for companies that develop a QMS for the wrong reason- to basically just hang up a certificate on the wall.

To be honest, many times you can make believers from non-believers; it is all in the set-up of the system. Many implementers when setting up processes, they made them rigid, difficult, and over documented. The QMS needs to be integrated to the business and it cannot be run as a “parallel universe.” It needs to make sense to the business, and it cannot be built just for sake of meeting ISO 9001 requirements or just because an auditor is going to ask for it.

3) What happened at other business should not happen at yours.

At another sales call, I met with a team of engineers that worked on sophisticated products in the aerospace & defense markets. They were interested in deploying AS 9100 for 2 reasons:

-

-

-

- Customers had implied this will soon become a contractual requirement

- They were going to start manufacturing operations and wanted to have a solid foundation in place to enable them to operate efficiently.

-

-

As we discussed, different options in terms of support and the way their Quality Management System would look we eventually started defining the scope of their system. As they explained how activities were organized in their business and how their growth will include new locations, we were defining how the QMS will support them. But halfway through the conversation, a question and statement caught me off guard. They said: “Can we exclude design activities? … a customer wants us to exclude design.”

Determining whether product design applies is a very common question. People are often confused about what the product design requirements implies and how it needs to be deployed. However, hearing that a customer was asking of its supplier to keep design out was a new statement for me. My potential customer explained that their customer appreciated their responsiveness and nimbleness with design and thought that if they added design onto the scope of their QMS then they won’t be able to enjoy the same service.

When ISO is set up correctly, it should not affect you negatively. If your customer has experienced delays before with other companies or within their own QMS, then it probably means that the process for design was not created to work to their advantage. Their process was not simple or nimble enough. Don’t blame ISO for their bad implementation. Bureaucracy, inflexibility and complex approval processes are self-imposed, and truly is more a reflection of the company’s own culture rather than of ISO 9001 or AS 9100 requirements.

Recap on how to turn ISO haters into lovers

If you did not fall asleep by now, in order to make sure we reduce the amount of ISO haters out there remember these three commandments when implementing any ISO standard:

Let us know if we can help you get ISO certified.

We have 3 different consulting programs that we believe will fit your way of doing things.

When FQ sets up QMS for our customers we make sure that our customer can see/feel the value to it, that it is a company activity and that it makes sense to your business. We don’t do anything just to meet requirement, get the certificate, and we certainly DO NOT LIKE OVER-COMPLICATING YOUR LIFE WITH HUNDREDS OF DOCUMENTS YOU DO NOT REALLY NEED.